Recognize and measure

Research and development in the field of image processing can be oriented quite differently. On the one hand, advances in the definition of a theoretical mathematical model for digital images provide important foundations for the understanding of image acquisition and interpretation. On the other hand, rapid developments in the field of robotics and the use of neural networks for visual sensors in industrial practice go hand in hand. Within this field of conflict, the IAB is working in the field of model-based, camera-based object detection and optical measuring. When monitoring production processes, image sensor-based factory automation and quality assurance, the employees in the competence area of process analysis and control are the appropriate contact persons.

Object recognition and object measurement

The main emphasis is on object recognition and measurement with intelligent optical sensors. Special emphasis is on production monitoring processes such as image sensor-based automation in production or quality assurance.

Process optimization

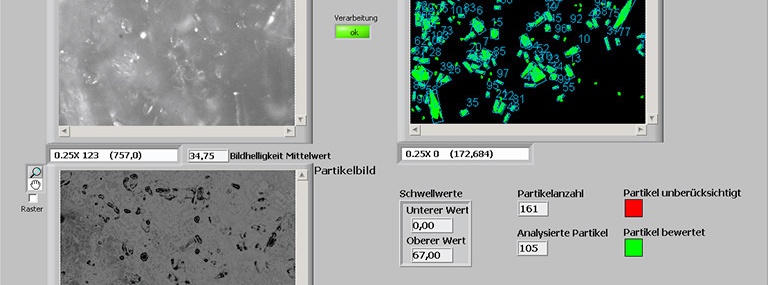

An example from the process monitoring is the Alpha-Gypsum project. Within this research project, the crystal forms occurring in the plaster production process were determined using image processing methods and were statistically evaluated. With an increased proportion of unwanted crystal forms, the plant operator can consciously take counter measures, thus optimizing the production results qualitatively.

Quality assurance system

The quality assurance system for the production of concrete blocks implemented at IAB Weimar automates the replacement process. With the help of image processing controlled robot, concrete blocks that do not meet the quality guidelines and are defective, can be sorted using robot thereby eliminating physically exhausting work processes.

Quality control and process monitoring

For quality control and process monitoring, we have a project called bubble-point test. The test setup for filters serves to rule out possible material and manufacturing defects.

Robust monitoring systems

The live trap is an intelligent device to capture animals in the wild and to relocate. The latch mechanism of the trap is activated only when the image processing system has uniquely identified the predetermined species.

Recognize and measure

Research and development in the field of image processing can be oriented quite differently. On the one hand, advances in the definition of a theoretical mathematical model for digital images provide important foundations for the understanding of image acquisition and interpretation. On the other hand, rapid developments in the field of robotics and the use of neural networks for visual sensors in industrial practice go hand in hand. Within this field of conflict, the IAB is working in the field of model-based, camera-based object detection and optical measuring. When monitoring production processes, image sensor-based factory automation and quality assurance, the employees in the competence area of process analysis and control are the appropriate contact persons.

Object recognition and object measurement

The main emphasis is on object recognition and measurement with intelligent optical sensors. Special emphasis is on production monitoring processes such as image sensor-based automation in production or quality assurance.

Process optimization

An example from the process monitoring is the Alpha-Gypsum project. Within this research project, the crystal forms occurring in the plaster production process were determined using image processing methods and were statistically evaluated. With an increased proportion of unwanted crystal forms, the plant operator can consciously take counter measures, thus optimizing the production results qualitatively.

Quality assurance system

The quality assurance system for the production of concrete blocks implemented at IAB Weimar automates the replacement process. With the help of image processing controlled robot, concrete blocks that do not meet the quality guidelines and are defective, can be sorted using robot thereby eliminating physically exhausting work processes.

Quality control and process monitoring

For quality control and process monitoring, we have a project called bubble-point test. The test setup for filters serves to rule out possible material and manufacturing defects.

Robust monitoring systems

The live trap is an intelligent device to capture animals in the wild and to relocate. The latch mechanism of the trap is activated only when the image processing system has uniquely identified the predetermined species.

Development of smart texture sensors

- Locally resolved color and intensity measurement with spectrometer

- Statistical pattern characterization (linear binary patterns, histogram correlation)

- Application of a “cell wall model” with a watershed transformation

- Modeling of line structures as a “minimal spanning tree”

Process monitoring under unfavorable image acquisition conditions

- Optical process analysis with Particle Image Velocimetry (PIV)

- Data acquisition and evaluation with process microscope

- Use of FPGAs to minimize processing times

- Visualization of highly dynamic processes with high-speed camera

Robotvision in the construction industry

- Real-time handling of regular objects in partially hidden scenes

- Assessment of dynamic processes on machinery and structures

- Use of mobile optical subsystems for the detailed measurement of extended objects

- Geometry model setup and interpretation with 3D scanner