Machine Learning and Big Data Analytics

Machine Learning

From sensor selection and control integration to monitoring with mobile end devices – we provide you with competent and goal-oriented support for your application-related development needs.

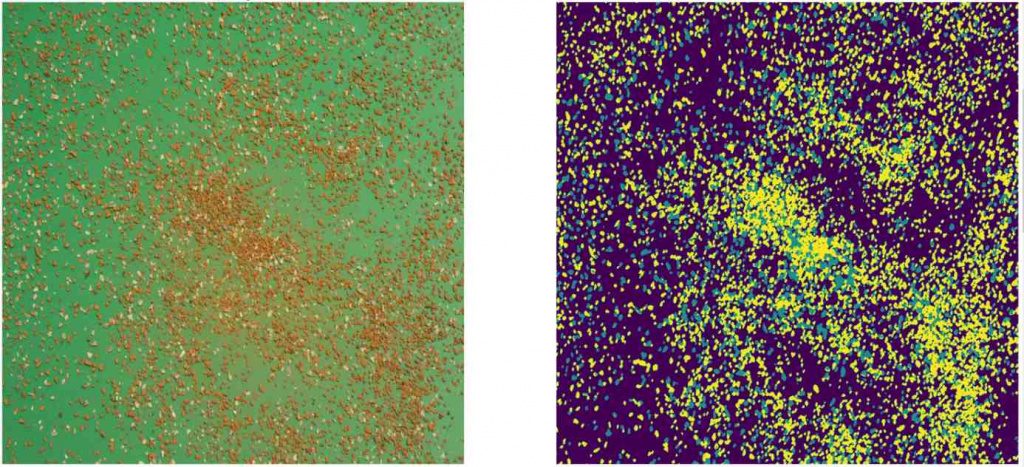

Due to the shortage of skilled workers and the resulting automation pressure in industry, it is becoming increasingly important to delegate tasks that are traditionally performed by humans to digital systems. With artificial intelligence methods, which include a large toolbox of statistical and numerical procedures, it is possible to train algorithms that solve complex tasks reliably and quickly. These methods are already being used in quality control and sorting tasks.

Big Data Analytics

If you are confronted with a large flood of data in your projects, we will be happy to support your project and translate your problem into concrete data collection and analysis steps that will enable you to fundamentally improve your understanding of the system.

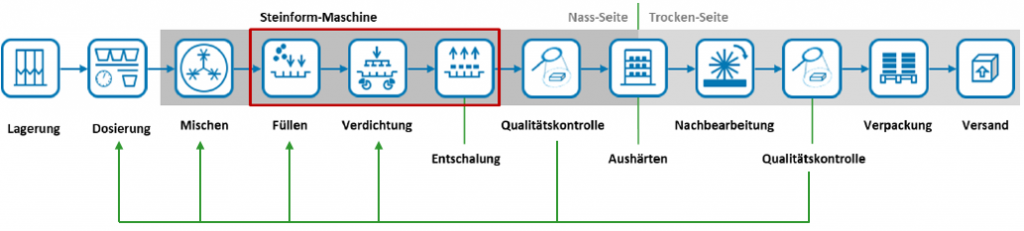

Production processes sometimes generate large amounts of data, for example machine, material or environmental parameters as well as human-machine interactions. Combining this information, analyzing it and generating models and predictions based on it can help to identify and understand complex interrelationships and to make strategic decisions. An exemplary question would be how the interaction of individual parameters in concrete production affects the concrete block quality. Based on this, predictions can be made that can possibly be used to reduce rejects or optimize recipes. It is also possible to analyze which producers and storage facilities are needed in regional energy networks in order to ensure security of supply while at the same time maintaining high ecological and economic efficiency.